Robinson Armament XCR-L Micro

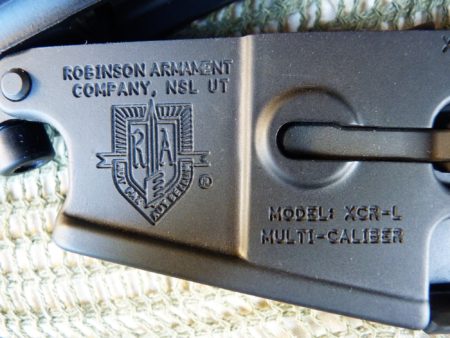

The XCR system (for Xtreme Combat Rifle) was developed by Alex Robinson in 2004 and released in 2006. The initial objective was to compete in the US Army’s SCAR project (Special operations Combat Assault RifleAn assault rifle is a weapon defined by the use of an "inter... More). The XCR was ultimately not evaluated by the US Special Operations Command (SOCOM), probably for a purely logistical and administrative reason: the blank firing adaptor would not have been provided on time to the evaluation commission! The system continued to be developed and improved for about ten years, naturally targeting the American civilian market, but also certain administrations or special units. Having undergone many improvements since 2006, the weapon reviewed here is the 2017 variant model. It is imported by the BGM gun dealer well known to French sports shooters.

When we talk about a semi-automatic long weapon in .223 Remington / 5.56×45 or .308 Winchester / 7.62×51 from the United States, the average (but initiated!) shooter immediately and almost exclusively thinks of the many clones of AR-15 and AR-10 weapons. It must be said that this system has a virtual monopoly on importers’ catalogues. Let’s say that a new weapon and a “new concept” brings freshness and personally a lot of satisfaction!

The XCR system has many advantages. In its design, it is reminiscent of some precepts of the Stoner 63 developed by Eugen Stoner at Cadillac Gage in the early 60s. The inventor of the AR-10 and AR-15 had continued the design of weapons by attempting to correct the well-identified defects of the AR-15, including the conduct of gases inside the bolt carrier. Thus, after working on the AR-16 (in 7.62×51 which will become AR-18 in 5.56×45 in the hands of Arthur Miller) at Armalite, he will work on the modular weapon concepts called Stoner 62 (7.62×51) and 63 (5.56×45). The latter, finalized as the Stoner 63A after the departure of E. Stoner and his team at Cadillac Gage has become mythical in some circles. This series of weapons could easily be converted into rifles, carbine and two light machine gun configurations, even modifying the trigger mechanism and feeding system. The weapon is operated from a long stroke gas piston system, which had already proven itself on many MG but also on the famous family of weapons developed by Mikhail Timofeyevich Kalashnikov. The XCR therefore has a similarity with the Soviet family of weapons: the piston is connected to the bolt carrier when firing. This is an argument put forward by the manufacturer to promote the reliability of its weapon. In addition, it should be noted that Robinson Armament knows the Stoner 63 well: the M96 Expeditionary Rifle, a weapon produced from 1999 to 2005, is none other than an adaptation of the Stoner 63, with the bonus of a multi-caliber component (5.56×45, 5.45×39 and 7.62×39). By the time we are writing these words, the firm is currently studying the possibility of producing this weapon again. The XCR series has other interesting features among which:

- Ambidextrous commands. Note on this subject that the cocking handle present on the left flank is reputed as ambidextrous by the manufacturer: far from us the idea of heating the debate, everyone will make an opinion. Still, some weapons have solutions for each side of the weapon, either permanently (G36) or by part transposition (FN SCAR).

- Simple disassembling and maintenance.

- Few constitutive parts.

- Construction of the upper receiverand handguard in a monolithic way. This is a point sometimes criticized by the architecture of the AR-15.

- Fixed ejector.

- Primary extraction.

- Easily interchangeable barrel.

- Compatibility with STANAG magazines.

For this review, we chose the shortest model in the catalog: the XCR L Micro with a 7.5-inch (19.05 cm) barrel. We believe that the .223 Remington (and by extension the 5.56x45mm) is “only” relevant in 20-inch (50.8 cm) or even 16-inch (40.64 cm) barrels. If this reflection remains true from a ballistic point of view, the concept of a compact weapon on the edge of the PDW (Personal Defense Weapon) interested us here. Also, it seems necessary for us to question our achievements (even, our prejudices!) and to have at least a curiosity for any type of material.

The 2017 range was largely available in France at the time of writing. They are classified in France at the time of writing as category B-4 or B-2 weapons. It therefore requires a special authorization issued by the prefecture of the place of residence, which will be granted only to sports shooters who meet certain criteria that we will not expose here.

The XCR range is available:

- In “M” version for the .243 Winchester, .260 Remington and 6.5 Creedmoor and .308 Winchester calibers with 9.5-to-20-inch guns (24.13 to 50.8 cm)

- In “L” version for the .223 Remington, .300 AAC Blackout, 7.62×39, 6.8 SPC, .224 Valkyrie and 6.5 Grendel calibers with guns from 7.5 to 18.6 inches (19.05 to 47.24 cm).

Both variants are available around 4 lengths of upper receiver: standard, competition, mini and micro, whose handguards can be standard M-Lock or KeyMod. Everything is issued with different types of stock and two types of gas operation: long stroke piston called Gas Block 3 or GB3 and short stroke piston called GB2. We will return to gas operation later in the same article. In any case, we are undoubtedly facing a “modular” solution in all its definition. We can point out here that for the US market, the Robinson Armament site has a weapon configurator with all necessary features: we highly recommend that you check it, it is worth your time!

Adequate operational and industrial solutions

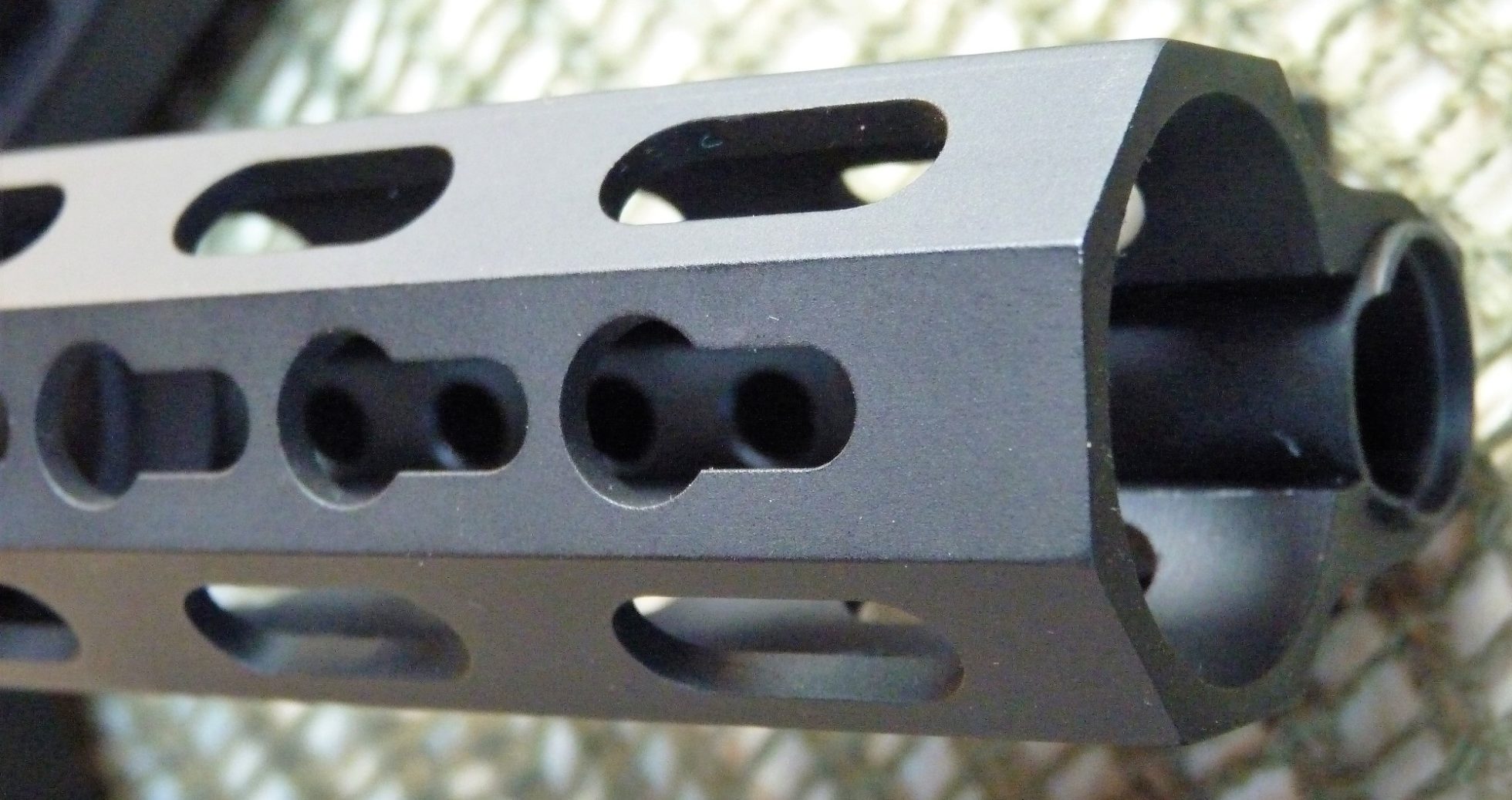

Our example is extremely compact and lightweight: 61 cm for 2.5 kg. The upper receiver is overall of rectangular shape. It is machined on an extruded aluminum of “aeronautical” quality type 7075T6. It can be noted here that the construction of the aluminum weapon is at first glance a departure from that of the Stoner 63, whose frames are built of stamped sheet metal (as well as the case of the trigger group). If the solution of stamped sheet is resolutely economical for mass production, it is very different for a more confidential production. Also, in the age of the CNC machine, the choice of aluminum seems wise. Finally, the choice to make the upper receiver from a machined extruded aluminum (choice also made on the FN SCAR) and not forged is an industrial solution that could be located halfway between the stamped sheet and the forged / machined sheet. A clever solution, whose spirit may not be so far from that of the Stoner 63. As already mentioned, the handguard is an integral part of this receiver. On the upper part, a Picatinny rail allows the mounting of optics or accessories. The sides and the lower part are KeyMod standard on our sample. The exterior finish is matte black, with the parts being treated with hard anodizing (Type 3). Many finishing options are available. On each side, openings allow ventilation of the barrel and the gas tube: for this “Micro” version there are 30 openings including the KeyMod slots. The steel gas tube is inserted into the receiver (Pic. 4). It enables to guide the piston and channel the gases taken from the gas block. Its lower part has 4 wide vents intended to evacuate the gases taken after pulse of the piston. The gas block (GB3 on our sample) is plugged on this tube (Pic. 5). A hexagonal screw secures the barrel to the upper receiver (Pic. 6). It is positioned at the front of the hinge allowing the linkage to the lower receiver.

The cocking handle is positioned on the left flank of the upper receiver: it is not attached to the bolt group and therefore does not move during shots (called non-reciprocating). Its button is well proportioned, cylindrical and rubber-sheathed. This handle can be used as a forward assist by pressing the button towards the inside of the weapon and pushing forward. The fixed steel ejector is bolted into the upper receiver: this method of implantation is made necessary by the use of aluminum for the construction of this receiver (Pic.7). In addition, it is a welcome simplification of production and maintenance. The use of a fixed ejector is one of the evolutions also introduced on the Stoner 62 and 63. When this type of ejector is properly integrated into the weapon, it has a significant gain in reliability compared to a spring-loaded ejector. Indeed, the power of the ejection is here related to the cycling-rate of the weapon and not to the power of a spring. Therefore, an over-cycle here leads to a stronger ejection where in a spring-loaded ejector weapon, the over-cycle limits the time allotted to the exit of the weapon receiver, which can produce “stovepipe” type jams. As a reminder, a “stovepipe” is a jam that implies that the spent case remains blocked between the mobile group and the receiver when the slide closes. Finally, this design choice protects from problems related to the weakening of the ejector spring. These are not as rare as one might think on a professional weapon with intensive use… Let us complete this point by evoking the sub-cycle problem: whatever the ejection method is, a sub-cycle generally results in a “failure to feed” type of jam. The moving assembly usually does not go far enough to properly account for a new munition. So, no need to worry about ejection in this case…

The synthetic brass deflector is attached to the back of the ejection port (Pic.8). The latter is relatively narrow and, like the FN SCAR or the HK G36, lacks a protection component. On these weapons, such a device is useless: the “sealing” against the foreign body is ensured by the closure of the bolt carrier which ensures an excellent sealing of the ejection port. Is it necessary to clarify that this is not the case of the AR-15… or a StGw-44? (Pic.9 and 10) The profile of the upper receiver has two side guide rails allowing the movement of the bolt carrier group (Pic.11). On the rear part of the left side of this same receiver, a rectangular opening is machined: it accommodates the rear end of the recoil spring assembly (Pic.12). This end, which features the receiver lock button that protrudes out of the receiver, locks the upper on the lower receiver. These two receivers are articulated on their front part by a captive pivot pin of the lower receiver. A similar use of the rear end of the recoil spring assembly can be found on the Ultimax-100 from the Singaporean firm CIS. The thing is not so strange, the two weapons clearly having a common “Stonerian” filiation… We can note that the assembly of our sample of the upper and lower receiver of the XCR has no gap.

A redesigned lower receiver

The lower receiver is also made of aluminum and receives the same finish as the upper. It is compatible with the grips of AR-15, a classic A2 model equipping our sample. All the controls on the lower receiver are ambidextrous, a point rare enough to be emphasized. The safety lever is at the height of the thumb of the strong hand. In the low position it allows shooting. Its rotation is barely 30 ° allowing a fast action. As is often the case with American weapons, security can only be engaged if the trigger mechanism is cocked. The right lever can be disassembled easily if desired by the user. On militarized versions, this selector has as an automatic position, placed in front of the semi-automatic position. The button of the magazine release on the right of the receiver is inspired by that of the AR-15. It is doubled by a command on the left to activate it. To do this, a lever has been placed on the back of the lock: it allows to pull the magazine lock from the left. The bolt catch is present at the base of the magazine well, two side ears allow it to be lowered to release the moving assembly or raised to block the bolt carrier assembly at the rear (Pic.13). As usual, the bolt catch is automatically controlled at the end of the magazine by the follower. The trigger guard is wide, allowing shooting with gloves without the need to disassemble its base as on the AR-15 system. The trigger is excellent without scratching or soft running (Pic.14). With double stage, it allows to perfectly feel the hard point before the release. It has a particularly short reset point allowing quick shots. The trigger mechanism does not have parts in common with those from AR-15 type, which allows the manufacturer greater flexibility in these design choices.

The barrel is therefore easily removable via the hexagonal screw positioned under the upper receiver. The indexation of the barrel is carried out via this screw and by the box which operates the gases. Its back part is extended by the locking nut (Picture 15). The major advantage of this arrangement is to be able to quickly change configuration and barrel length, or even caliber. Maintenance is also easier. The barrel of our sample is made of 416R stainless steel. It receives a matte finish, presumably obtained by glass bead blasting. Robinson Armament also offers 4140 or 4150 steel barrels whose bores and chambers are chrome-plated. All the barrels of the firm are made by button rifled. Here too, it is necessary to understand that the building of cold hammer forging barrels is profitable only on very large series.

A flash suppressor of our example and A2 type. The thread of 1/2”x28 makes it possible to replace this accessory by another device. The manufacturer’s website also offers (when this review is being written) their replacements by two variants of muzzle brake. Please note that on a version with such a short barrel, the choice of sound moderator must be done with care at the risk of seeing the device being degraded quickly … or even destroyed (Pic.16)! The adoption of a blast reducer device can also be a coherent alternative… but given the lengthening of the weapon and the increase in weight, isn’t it worth to invest directly in a longer barrel? Everyone will get an idea, but from our point of view, the interest of such a short weapon lies precisely in its low bulk. The barrel has 6 right-handed grooves at a pitch of 7 inches (177.8 mm) to stabilize heavy projectiles of 62 or even 77 grains. Other twisting rate are available. The gas block is positioned on the front third of the barrel. As a Gas Glock 3 type weapon it has 8 adjustment positions (from 0 to 7) to adjust the flow to the use of specific ammunition or a sound moderator. According to the manual, the adjustment can be made with the tip of any ammunition. Gas regulation is carried out in intake. Moreover, if you want to enliven the discussions between shooters, ask if the use of a sound moderator implies increasing or limiting the flow of gases… The answer is simple: the addition of a moderator is equivalent to the “lengthening” the barrel. With equivalent ammunition, it is therefore necessary to reduce the impulse to avoid the phenomena of over-cycles, induced by the direct gaseous pressure on the case after unlocking. This phenomenon of over-cycles is easily noticed by the increase in the rate of fire on a weapon firing in bursts: commonly, the weapon takes up to 20% of cyclic rate.

An atypical bolt carrier group

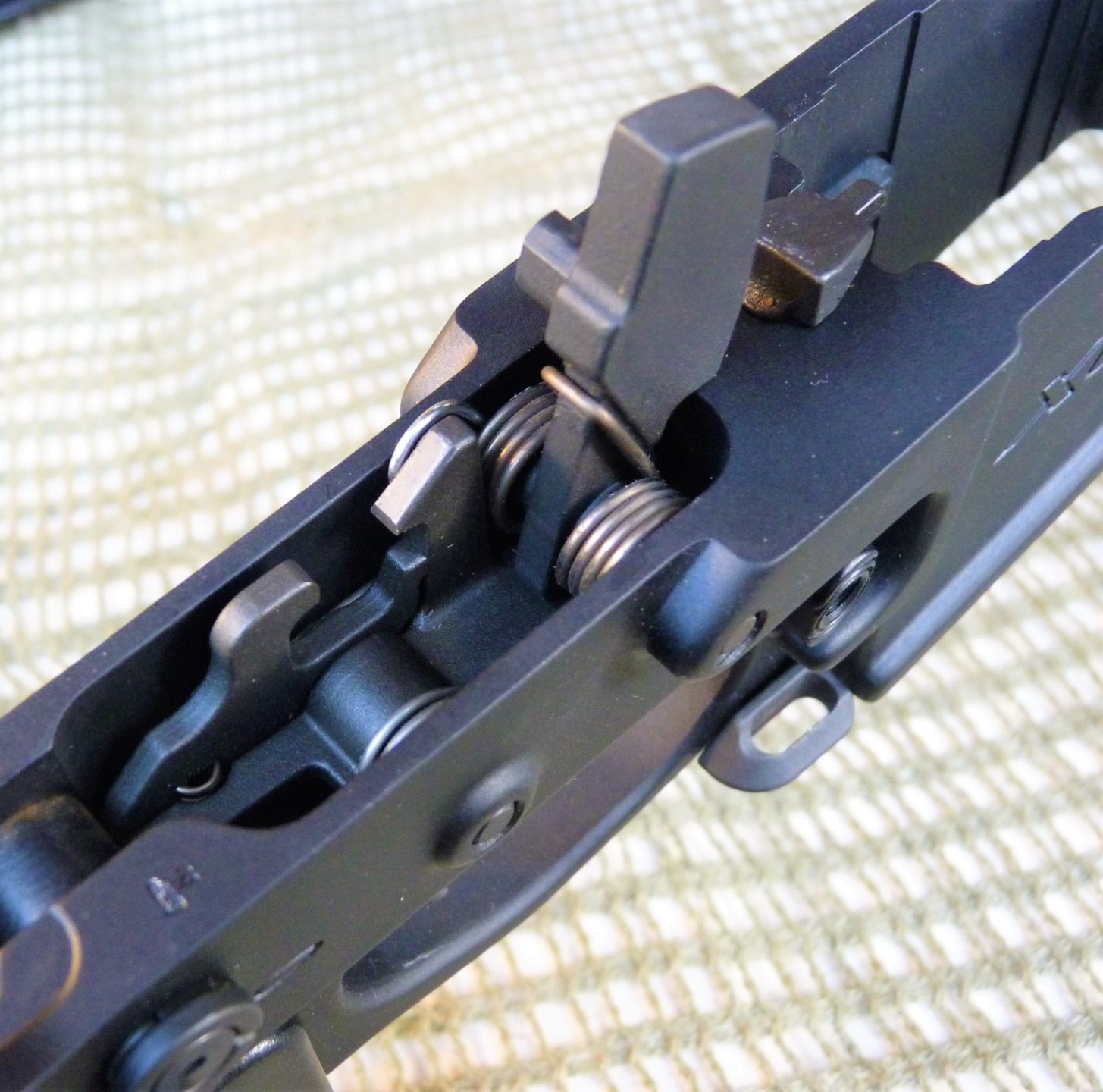

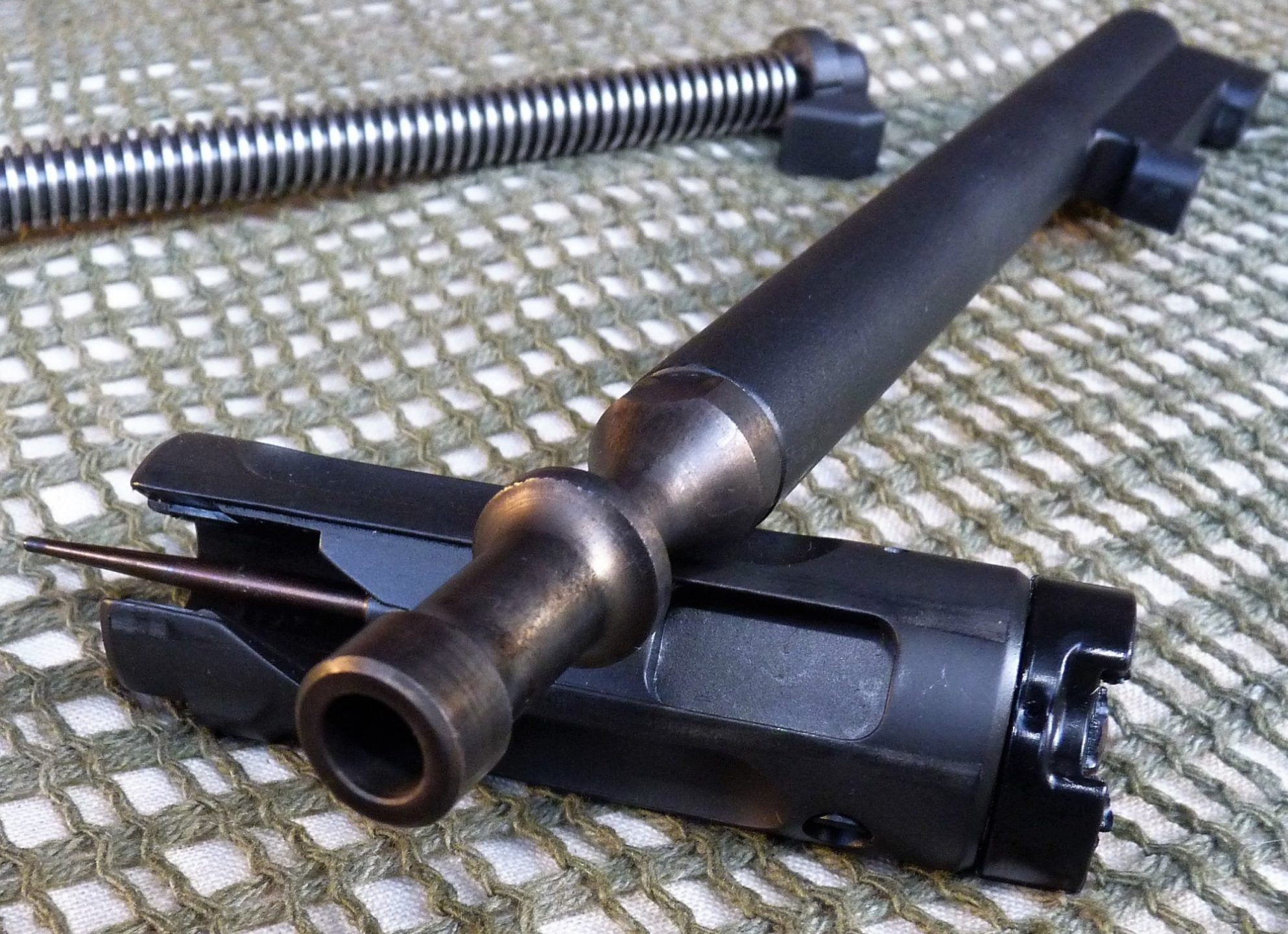

As on few long stroke piston weapons and unlike the Stoner 63, the piston separates from the bolt carrier when disassembling the weapon (Pic.17). This piston is composed of two parts. Its head has a cavity (Pic.18). The base of its rear part has two lugs that ensure the connection with the bolt carrier. The two elements are just nested and held in position in the upper receiver (Pic.19). The rear piston part is hollow to receive the recoil spring assembly. The rear end of the latter has the previously mentioned receiver lock allowing the assembly / disassembly of the weapon.

The bolt carrier is cylindrical, its left side is machined to allow the passage of the fixed ejector (Pic.20). The firing pin is attached to it by a pin. The latter remains pushed back by a captive spring of its rear socket (Pic.21). Thus, it does not meet the primer by inertia at the closing of the breech mechanism: these therefore theoretically protect the weapon from “slam-fire”. Note that like an AR-15, the firing pin is linked to the carrier and not to the bolt as on an AK. Thus, it can only protrude into the bolt faceThe bolt face is the part of the bolt which in set place the... More when the bolt is in the locked position. A buffer is clipped to the rear: it dampens the contact between the carrier and the rear part of the lower receiver.

The bolt is inserted into its carrier. A ramp practiced in the latter and ensures via a pin cam the rotation of about 30 ° allowing its implementation in the locking extension of the barrel (Pic.22). Cylindrical, the bolt has 3 wide lugs (Pic.23). We move away here positively from the “multi-lug” bolt originally designed by Melvin Johnson and taken up by Eugene Stoner on his weapons, Stoner 63 included. For the record, the only advantage of this bolt design is from a production viewpoint. One of the lugs incorporates a large extractor, which has the particularity of moving strictly perpendicular (by sliding) to the cartridge, a rather rare arrangement on a semi-automatic weapon. The left side of the bolt is also machined to allow the passage of the ejector. At the front of the left lug is a machined ramp: it ensures primary extraction during the unlocking movement by leaning on a ramp machined in the barrel locking extension (Pic.24). The primary extraction allows a better peel-off of the case from the walls of the chamber by associating a rotational movement with that of traction. This is a real added value in the context of professional use. The manufacturer also highlights the possibility of firing steel cases in its weapon, which notoriously tends to stick more easily than brass cases.

The stock (a “Fast 2” type on our sample) is originally foldable on the right side: it is raised and rotated in a similar way to a FAL Para type stock (Pic.25). However, current French regulations prohibit the possession of long guns with a total length of less than 60 cm. It is therefore necessary for this barrel length to block it in the unfold position in order to maintain a sufficient total length. The action on two side pushers allows the extension of the stock on one of the 6 positions. A lock adjustment knob makes it possible to tighten this adjustment (Pic.26). The butt plate is made of plastic with molded ribs, the cheek pad is adjustable with 2 positions. Despite compact dimensions, a medium-sized shooter (at least a French medium-sized people…) finds good shoulder contacts and the lack of movement in the stock is a real comfort.

The magazines are NATO Stanag 4179 standard. In practice, the majority of AR-15 (or AR-10 depending on the ammunition) magazines will be compatible. This is a point to be taken with a grain of salt without indicting any manufacturer here: we have already seen this alleged interchangeability being contradicted by the facts. The standard is probably not “standard” enough…

XCR are equipped with folding metal sights that appear to be proprietary (Pic.27). If some call them “back up” sights, their quality makes them perfectly exploitable elements as main sights. The front sight and aperture are protected by side ears. The front sight adjusts in height with the ad hoc tool for the M16A2. The aperture drifts laterally via a wheel. It has two openings: a wide one for shooting at close distances (0-200 m dixit the inscription) and in low visibility condition and one narrow for precision shooting. Mounted on the picatinny rail, these accessories are made of steel and of first quality.

Operation moving away from the AR-15

Our sample therefore operates from a long stroke gas system; it is also the case for the models using the gas block “GB0” and “GB1” previously marketed by the Salt Lake City firm. The action of the gases allowing via the piston to ensure the unlocking of the bolt. Under the action of the gas, the piston is impulse backwards, driving the bolt carrier. During this recoil, the carrier gives the bolt a counter-hourly rotation of 30 ° via the ramp. This ensures the unlocking of the barrel extension, but also the primary extraction mentioned above. Thus impulsed, the bolt carrier group continues its recoil, finalizing the extraction and then producing the ejection of the spent case when it meets the fixed ejector. The recoil spring assembly returns forward the bolt carrier group generating, taking the ammunition from the magazine, its chambering and, finally locking the cylinder head. On the GB2 version also offered as an option, the piston of the short stroke system remains captive into the gas block as on an M14. The benefit of this provision is a better contingency of the gases, and therefore a lower fouling of the weapon. The counterpart is a push that is stopped at the end of the piston stroke, which earned it the qualifier of “short stroke”. The thing is actually very dependent on the integration of the device within each weapon: for more details you can refer to chapter 6 of the Small Guide to Armament online on this website. Note also for purists that barrel and bolt refer to the military ammunition of 5.56, only the carrier is marked for the civilian .223 Remington… (Pic.28). According to the manufacturer, regardless of the marking of their weapons, they are capable of setting fire to both types of ammunition interchangeably.

The XCR is particularly simple for disassembly and maintenance (Pic.29). Once you have made sure that the weapon is not loaded nor supplied, bring the bolt carrier group forward. Push the receiver lock on the left back of the top receiver forward and rotate the top receiver to the axis. The bolt carrier group is extracted from the rear. Be careful to “ensure” the different parts during the extraction of the assembly, they do not have mechanical retention and their consistency is only ensured by their integration within the upper receiver. The recoil spring is separated from the piston, which separates itself from the carrier. The bolt is removed from the front of the carrier after removing the piston. After removing the pin present at the rear of the bolt carrier, the buffer and the firing pin are free. The upper receiver separates from the lower receiver via the captive pin located on the front of the lower receiver. The barrel can then be released as previously indicated. Once the barrel is disassembled, the weapon manual tells us the gas tube can be removed from the front using pliers: we did not feel the need to carry out this operation for routine maintenance operations. The ejector and brass deflector can be removed as well as the gas block adjustment screw, however in common use this procedure is not necessary.

The XCR facing the target

We carried out different types of shooting at 100m, both from a rest and from standing position. All the operations are simple and reliable. We appreciated the side cocking handle much more practical than that of the AR-15, as well as all the ambidextrous controls. The balance with a full magazine is positioned at the front of the magazine well. The XCR has got a naturally intuitive target acquisition. The double stage trigger allows excellent releases: its short reset allows quick shots on the reactive silhouettes. The blast effect related to the escaping gases at the mouth by the time the bullet lives the barrel is important: the 7.5 inches of the barrel really seem to us to be below the minimum for this caliber. Nevertheless, as often in such circumstances, the shooter is quite spared: it is the neighbors on the shooting range who benefit the most! However, it is necessary to be aware that the professional user can find himself in confined places at the time of shooting, and thus “benefit”, too, from all the “production” of his weapon … The ejection is powerful and regular, the cases are propelled between 3 and 4m at 85 ° on the right, in this configuration it is still necessary to consider the infrastructure of the stand to avoid “inconveniencing” a neighbor too close … This is a reproach that can often be addressed to long guns equipped with a fixed ejector: their ejection is generally violent. The peak of the problem is reached in our opinion with the HK G3 rifle in caliber 7.62×51: the “fixed” ejector combination (even if retractable) with delayed blowback by roller produces ejections that should not be faced … This is undoubtedly the ransom of reliability! To return to the XCR, remember that the presence of a brass deflector protects the left-handed shooter from an ejection too much on the rear: the weapon is therefore fired from both shoulders without any risk.

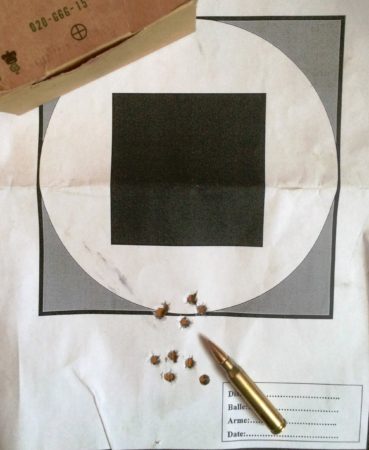

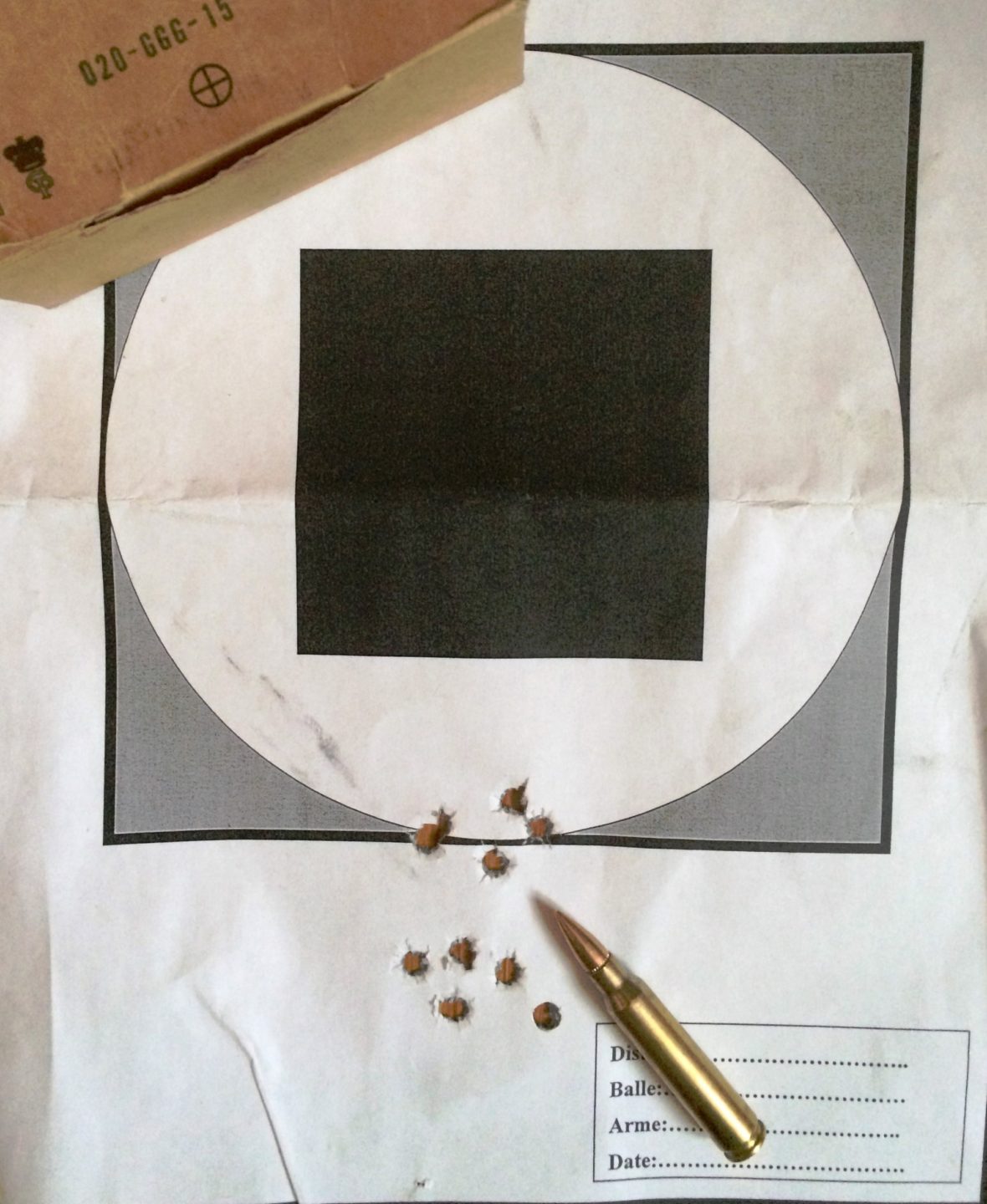

We fired precision shots at 100m, the weapon equipped with a Canadian Elcan M145 scope with a magnification of 3.5 (Pic.31). The shot group hold almost the minute of angle, which in view of the length of the barrel is a very honorable result (Pic.32). This is also the performance announced by the manufacturer. A positive point more, at the end of the shots the weapon is rather clean, breech and carrier are not soiled by the residues as on an AR-15. Cleaning is greatly simplified.

All the shots were carried out with Lithuanian ammunitions GGG of 4g (62 grains): these ammunitions of excellent quality are to the NATO standard and use a bi-metal projectile of the SS-109 type, also called M855 in the US Army.

Conclusion

For the shooter who looks for this type of weapon, the XCR range of Robinson Armament makes it possible to free himself from the “everything” AR, as it is true that the choice is today limited to different versions of the “black rifle” rather than to other systems… The XCR family is a really interesting alternative, offering remarkable performance and ergonomics for the price of a high-end AR-15. The level of finish of the weapon also is well in keeping with that of a high-end weapon. So, if you can afford it, we see no reason that you should restrain from acquiring this real American alternative.

Julien Lucot & Arnaud Lamothe

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!

Robinson Armament weapons are imported into France by BGM gunsmith: