The Chassepot artillery musketoon at the firing range

Several years ago, my professional activity regularly led me to small Parisian shops. I have always been surprised to discover places that seemed not to have evolved for several decades, generally sporting a decoration from another time and quite a bazaar. One winter morning, I set foot in a small press house in the 14th arrondissement that was soon to close for lack of buyer. The impression upon entering was striking, a leap of at least 30 years back in time! With time ahead of me, I went around the shop and bought my favorite weapon magazine. The owner then asked me the usual question: “Are you a collector”? Taking care to mitigate my answer, I answered her with the affirmative. And that’s when we switched to what every collector hopes to experience one day: the discovery of a rare and unexpected piece! In two sentences the owner informed me that her husband collected weapons for quite a long time, that there is one left in the reserve on an old rack and that she wanted to get rid of it quickly before closing her store.

After moving several boxes of unsold magazines, I found the aforementioned rack. That’s when my breath stopped, finding myself face to face with a Chassepot artillery Musketoon (Mousqueton d’Artillerie Chassepot) … the least common part of this weapon system! After a little bargaining and a visit to the nearest ATM, I came out with my musketoon packed in newspapers. As it stood, the weapon was not very presentable. Once covered with a large layer of grease that had turned into varnish, a complete disassembly and cleaning was in order. That very evening, I did what had to be done …

The context

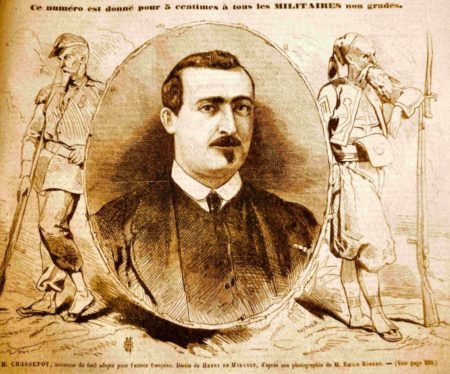

If the purpose of this article is not to go into detail about the genesis and evolution of the Chassepot system, some reminders are necessary. From the beginning of his reign, Napoleon III had wanted to modernize armament and military techniques. In this second half of the nineteenth century, technical and scientific advances in the midst of the industrial revolution were important. This period was rich in various innovations, and it was difficult to adopt a weapon system that could become obsolete in a few months. The geopolitical context and tensions with Prussia then precipitated the choice and adoption of the Chassepot system. France would acquire a paper cartridge weapon, while the first metal cases ammunitions were also under development. The adoption of a modern metal case ammunition would be done only eight years later, with the adoption of the 11 mm Gras.

Adopted in 1866, the Chassepot system with paper cartridge presented a major technological advance. In the first place, this system marks the crossing of a course in military industrialization: the manufacture of barrels was done from casted steel blanks and no longer forged steel. This cost-effective process for mass manufacturing required significant industrial resources. This technological choice would help to stimulate the creation of French arms factories by bringing together the various workshops that worked independently. The most emblematic is the Manufacture d’Armes de Saint Étienne, whose development dates back to this period.

Caliber reduction was also a major step forward. The transition from an 18 mm diameter bullet to an 11 mm one allows ballistics that were out of all proportion for the older systems, as long-range firing becomes much flatter by the speed gain that is associated with the reduction in caliber. The Chassepot’s paper ammunition was also innovative. It allows the breech-loading of the ammunition. The consequences are twofold: the soldier is no longer forced to expose himself to reload his weapon and the rates of fire are much higher. As a paradox, the real weak point of the Chassepot, like its rival the Dreyse, also essentially lies in its ammunition: fragile and complex, it generates shooting incidents during intensive use. The Chassepot will nevertheless remain a symbol of French armament, it remains the first “modern” infantry weapon by its caliber and its loading method. The weapon itself is without a flaw. It would also have an exemplary career since from 1874 a considerable number of rifles would be upgraded for the metal case cartridge of 11 mm Gras. It should be noted that more than 160 years after its adoption and for a period of service of only 8 years, the name of Chassepot still resonates in the collective consciousness of shooters and history enthusiasts alike. The Chassepot would be available in several variants: infantry rifle, Gendarmerie carbines on horseback or foot and artillery musketoon.

A bit of mechanics

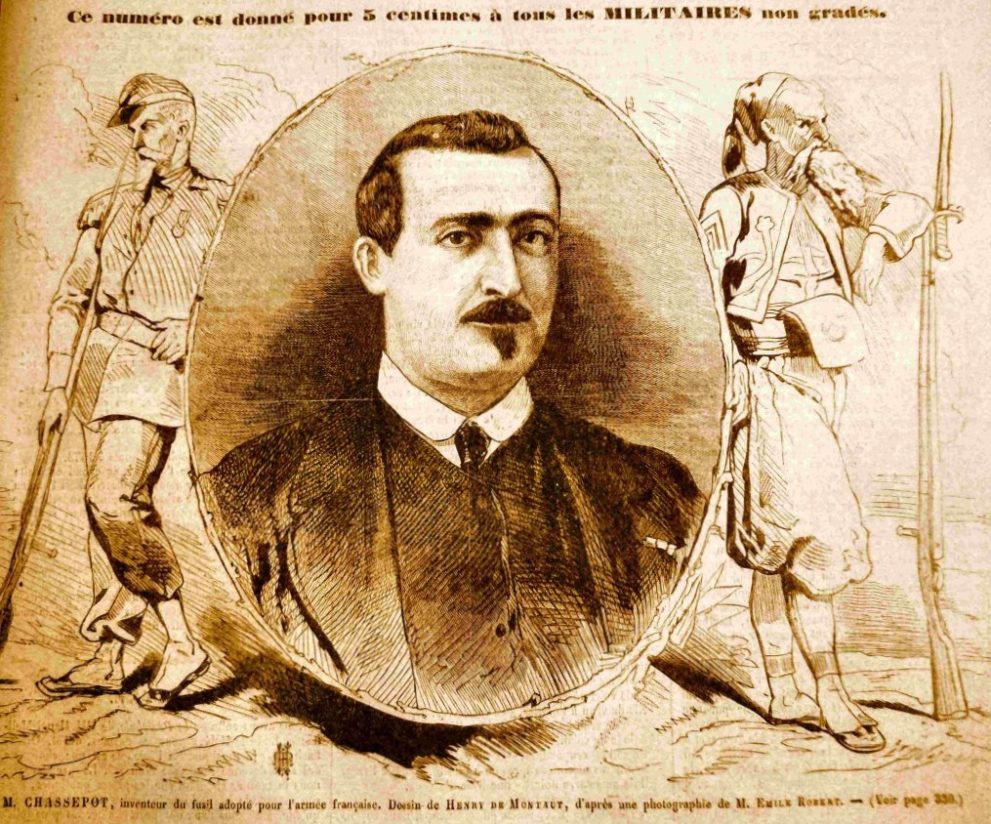

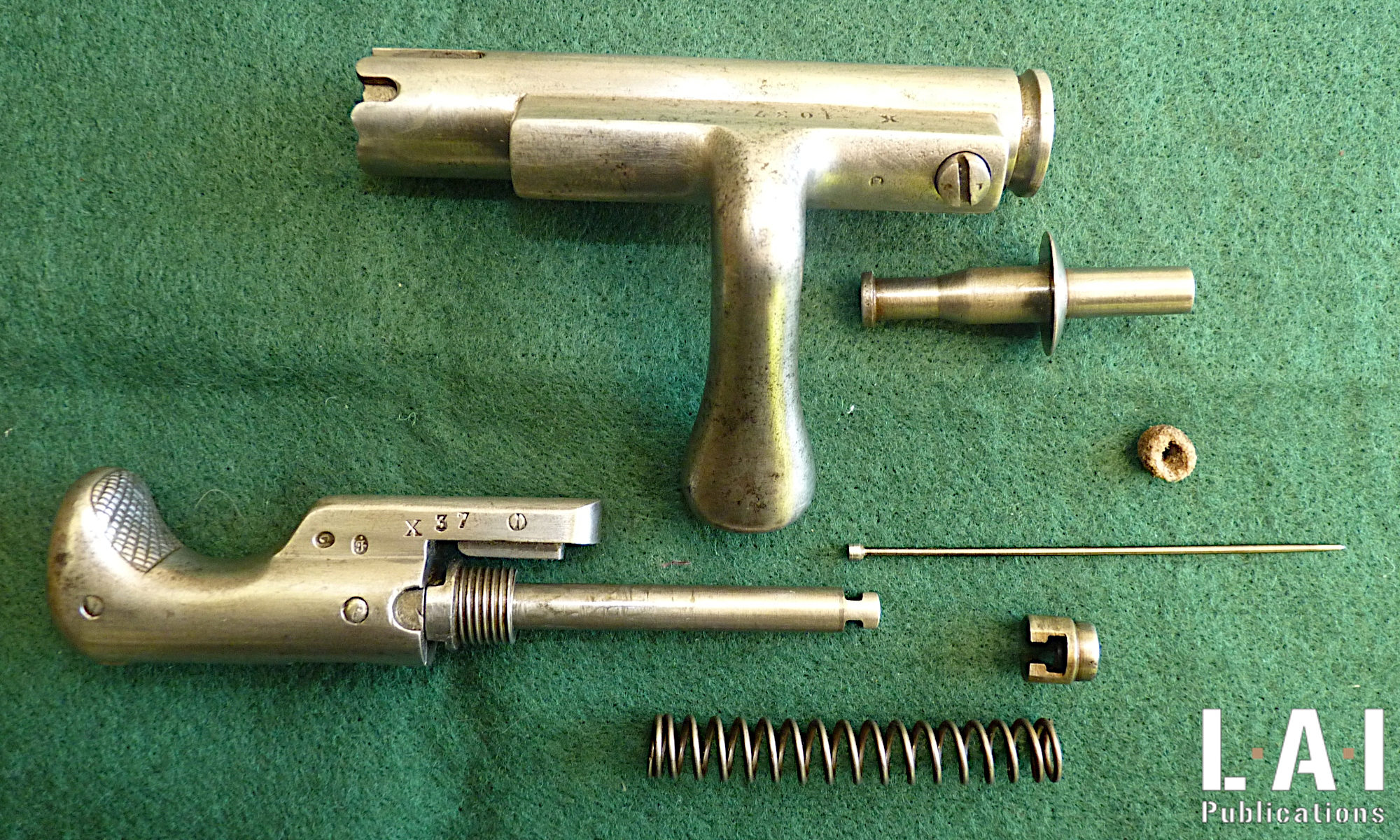

The operation of the weapon is close to the bolt-action weapons still very popular to this day. Equipped with a mobile bolt, the locking is carried out directly by a single strong lug that fits into the loading port of the receiver. The bolt handle is set on this lug. This system, which may seem “light”, since it is identical to the small so-called garden guns, is nevertheless sufficiently solid. As proof, it has been kept identically on the Gras system with metal case cartridge. Note that this bolt is not equipped with a helical ramp acting on the cocking piece, and that, therefore, cocking is carried out manually before opening the bolt and not automatically at its opening. To open the bolt and access the chamber, it is therefore first necessary to pull the cocking piece if it has been released.

Sealing during firing is ensured by a process that is as simple as it is effective. In order to protect the shooter and prevent the discharge of flue gases from the rear of the bolt, a rubber ring is mounted on the movable head of the bolt. During the firing, the gases come to press on the moving head which, by compressing, push against this rubber ring. The diameter of the latter expands and therefore makes the combustion chamber perfectly sealed on its periphery. The sealing is completed by a “grain”, a piece of leather intended to ensure sealing around the needle in the bolt body, in particular to avoid excessive and highly problematic fouling in this sensitive part of the weapon. We were able to witness the effectiveness of this system during our tests. It is reputed to be much more reliable and efficient than the Dreyse system, which relied on crushing a gasket at the forced closing of the bolt.

The weapon has a “needle” as a firing pin…which gave the fashionable nickname “needle gun” for this kind of weapon. The purpose of the latter is analogous to the striker, except that it must also pass through the rear end of the cartridge before coming to meet the priming system. The disadvantages associated with this system are essentially an increased fragility, the risk of nailing the primer, and a high sensitivity to fouling.

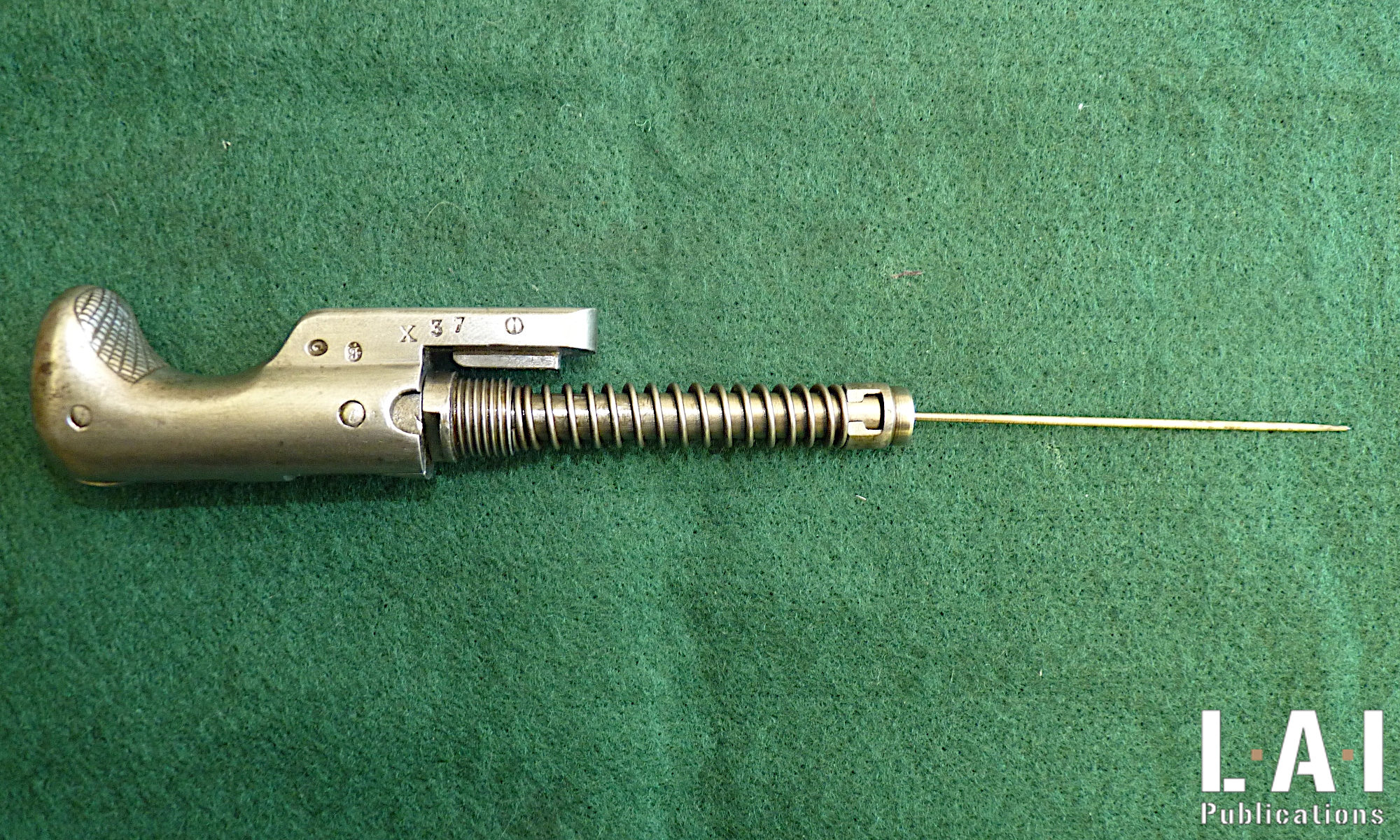

The artillery model

During the Franco-Prussian conflict of 1870, the lack of armament was obvious. The Chassepot had not been distributed to all army corps and more or less old weapons were put back into service: 1822 T Bis rifle, Tabatière rifle, etc. In this context, the artillery was in a special situation. If weapons of the Chassepot system had been developed for some units (Gendarmerie, Cavalry), it was not the case for the latter. The infantry rifle does not correspond to its needs, especially in terms of compactness. Thus, the artillerymen were still equipped with the musketoon 1829 T Bis, really obsolete because of its caliber as well as because of the way it operates.

In 1871, as soon as the conflict ended, an armaments commission studied the creation of a musketoon using the Chassepot system specific to artillerymen. Remember that from that date the Headquarter had become aware of the rapid need to adopt a metal cartridge, the Germans having adopted the ammunition of 11×60 R (called “11 mm Mauser”) for their Mauser 71. Nevertheless, for strategic reasons, many weapons having been destroyed or taken by the enemy, the weapon industry continued to produce to the maximum of the weapons of the Chassepot system. This choice can be explained in part by the adoption of the Gras system, which allowed both the subsequent conversion of the weapons produced but also the use of ammunition from older systems. It can be noted that the use of pre-existing weapon transformation has been a conventional industrial choice in terms of weapons since the beginning of the nineteenth century, and that being part of the “industrial landscape”, this decision does not seem surprising.

From 1871 a pre-series of artillery musketoons would be distributed in order to carry out a series of tests aimed at their adoption by the troops. Models were tested up until 1872 before this model was finally adopted. Manufacturing was exclusively devolved to the Manufacture d’Armes de Saint Étienne. About 50,000 musketoons of this model were produced, including the famous “X” series designating test weapons. In 1874, most of these weapons would be modified to fire the cartridge of the Gras system, which explains their relative rarity to this day. Note that the weapon subject to this article comes from the test weapons marked “X” by the armament commission in 1871, making it one of the most sought-after models.

This musketoon would serve as a standard for the future Gras musketoon model 1874, which would take over most of its characteristics. The weapon is really compact (especially for the time!), with a total length of less than one meter, or 99.3 cm. Its barrel is 48.9 cm long and has the particularity of being right-hand rifled, unlike all the other weapons of the Chassepot system, a feature that would be kept on the Gras system. The purpose of this reversal of the rifling of the barrels does not seem obvious to us: it is sometimes claimed that it makes it possible to correct the gyroscopic effect and to ensure a better stabilization of the bullet … We do not feel that this statement is justified form a purely logical perspective! Due to this specificity, the front sight of the test models is deported from 1.2 mm to 1.6 mm on the left. The rear sight is graduated up to 1200 m, in combat position it indicates a practical range of 150 m. The bayonet is identical to the infantry model’s, namely the 1866 model with Yatagan blade. The installation of the bayonet adds more than 50% to the length of the weapon which thus reaches 1.57 m!

Note that this variant of the weapon has in the past been the subject of a large number of copies, usually shortening rifles of the same system. The fact that the grooves are reversed allows a first guarantee of authentication. For the rest, it is necessary to control the production manufacture, the production year and the various control hallmarks.

Shooting preparations

The routine disassembly of the weapon is easy to achieve, it is both simple and traditional. The bolt is more complex to disassemble and requires specific tools to disassemble the needle nut and release the needle and percussion spring support. It is actually enough to modify a 9 mm wrench by reducing its thickness. Note that the bolt must be systematically and completely disassembled after each shooting session in order to carry out the complete cleaning of its elements.

The original ammunition that has come to us in good condition is relatively rare. It is, of course, not reasonable to try to fire or dismantle these ammunitions, which are real relics. The cartridge consists of the paper powder case covered with silk gauze. Bearing the primer at its base, the latter is in direct contact to the compacted black powder that will act as an anvil during firing. This consists of a copper capsule, a rubber washer, a stamped cardboard collar and a ten-pointed paper star. A pierced cardboard washer closes the case at the top. The central hole of this washer serves as a housing for the twisted end of the powder case paper. The bullet engaged in a rolled and glued paper cone is placed on the case so that it rests on the pierced washer. The set is then bound with a wire that goes around twice a little below the puck. The entire head of the cartridge is greased with a mixture of sheep tallow and yellow wax. From 1867, the base would also be lubricated with virgin wax. The velocity of the bullet reached 410 m/s in the service rifle. The diameter of the bullet was 11 mm, for a cartridge diameter of 14 mm. The total length was 67 mm for a weight of 31.8 gr.

For our tests, we specially crafted ammunition. When we talk about the crafting (and not the reloading!) of Chassepot cartridges, most shooters evoke the difficulty of doing so, the necessary equipment, the time and the know-how … I must confess that this is not the case. It is in fact of a biblical simplicity, or close to it. The necessary budget is very low, most of the components (primers, bullets and powder excepted) are from recycling elements. For the necessary time, let’s say that obviously it requires learning and that a few hours of practice are necessary… To illustrate my point, let’s say that I am unable to “roll” a cigarette, but that crafting these cartridges is not a problem.

I will not go back over the details of the production operations; I have conformed to the excellent work of my friend Jean Pierre Sedent. The latter has carried out a remarkable and ingenious study, allowing everyone to craft their own cartridges. All the information is visible on its website jp.sedent.free.fr (in French only…), it is affordable and technically very detailed. In order to cross-reference the sources, Luc Guillou also detailed an interesting procedure because easy to understand and reproduce in issues 307 and 310 of the French magazine “Action Armes et Tir” of 2007.

It is just worth remembering that the necessary material consists of a mandrel, a roll of thermo-treated paper for a cash register, a cardboard plate and a tube of glue. The cartridge consists of a tube receiving the powder and the filler, this tube being closed by cardboard shutters, the first of which includes the priming system.

First of all, before any step, it is necessary to ensure the state of conservation of your weapon, either with a professional or by yourself if you have the required experience. A complete disassembly and a search for anomalies is essential, in particular wear, corrosion, stock repairs, etc. Wearing protective glasses is essential, as the risk of gas leakage is real. On the weapon, there are 3 elements that can be considered consumable: the rubber ring, the firing needle and the grain. If in doubt, systematically replace these elements. I insist on the role of the rubber ring: it is the essential element guaranteeing the tightness of the chamber and therefore the safety of the shooter. It should be changed regularly for a new model of good quality. When acquiring a Chassepot, I systematically advise to get new rings and needles and replace them.

At the shooting range

The tests were carried out at a distance of 50 m on a ISSF 25 m precision pistol target. On the target we present, 5 cartridges were fired with the weapon resting on a sandbag, then 5 cartridges fired from a standing position. The balance of the weapon is particularly advantageous. Relatively short, its center of gravity is located at the front of the trigger guard. The sight picture is sharp, although it is necessary to get used to a V-rise and a triangular front sight. No sight adjustment being possible, an important lead was necessary, the weapon firing 30 cm too high and too far to the right.

Loading the weapon is particularly easy: after opening the bolt (if necessary by having previously cocked the needle), the cartridge is pressed deep into the chamber with a finger. The bolt closes gently without excessive resistance. The trigger release on our weapon is particularly soft and accurate, the firing is carried out almost instantly, a sign that the loading protocol is effective. We fired 16 cartridges for this test, no hang fire occurred. Only one ammunition persisted in not igniting. After disassembly, the cause was highlighted, the powder charge having not been sufficiently packed, the needle pushed the primer without igniting it.

The recoil is pleasant, the weapon is “alive”, its weight and dimensions being less important than the infantry weapon. The detonations are pleasant. We fired outside the firing range, in order to hear the detonations echoing in the surrounding natural landscapes. Fouling is important, but nevertheless allows the firing of 5 cartridges without difficulty. However, we made sure between each shot that no significant residue clogged the barrel (cardboard, primer residue, etc.). Every 5 shots, the chamber was cleaned using a soft brush. The intense pleasure that we experienced made us forget the time spent to craft the cartridges, our cartridges-pouch was quickly empty. The tests have proved the weapon’s accuracy potential and the reliability of the ammunition, let’s just craft new cartridges again.

Like any black powder weapon, all components of the weapon should be disassembled and thoroughly cleaned quickly after every shooting session.

In conclusion

Reviving such a piece is really moving! The pleasure of shooting with a historic weapon is combined with that of producing one’s own ammunition. I often wonder about the following fact: in France many Chassepot are sold or traded on different exchanges or specialized sites while very few are used on French shooting ranges. The apparent difficulty in the crafting of the cartridges is in my opinion one of the main explanations. I had fun counting the time it took to craft the ammunition on about fifty pieces. All steps put considered, it took me less than 5 minutes to make a complete ammunition that costs me less than 1 euro. I hope that these few considerations will give rise to vocations and that some Chassepot will finally be taken out of their rack.

Julien Lucot

This is free access work: the only way to support us is to share this content and subscribe. In addition to a full access to our production, subscription is a wonderful way to support our approach, from enthusiasts to enthusiasts!

Warning

This review concerns a weapon at the author’s disposal and is not applicable to any weapon of the same caliber. Only the method is applicable depending on the condition of the weapon and components. The weapon in its entirety must be checked by a professional. The same is true for the bullet and the powder charge. Any reloading must be elaborated starting from minimum loads and progressing steps by steps.

Thanks:

Jean-Michel Pineau who actively participated in the tests illustrating this article.

Jean Pierre Sedent for his work (jp.sedent.free.fr) on the crafting of ammunition and its availability.

Sources :

Armes à feu françaises modèles réglementaires 1833 – 1918 by Jean Boudriot.

Issues 307 and 310 of Action Armes et Tir, 2007, articles by Luc GUILLOU

Mr. FORET Patrick of the website “Arme et Passion”, for providing pictures and information www.armeetpassion.com